Milling Machine

79,296 ResultsWhen you browse and shop through the various merchant links provided on this site, it may lead to this site garnering a commission. Participation in several affiliate schemes is a part of this site's operations, eBay Partner Network being one of them.

Browse Related

Milling machine buying guide

Before you buy a milling machine (new, used or refurbished), you need to know what you want to do with it and how much you're willing to spend.

Milling machines are used for a variety of manufacturing processes. They are often used for milling, drilling and grinding materials. The milling machine is a tool that uses rotating cutters to remove material from a workpiece. The tool can be moved in any direction with respect to the workpiece, which allows it to remove large amounts of material quickly. They're used to cut or shape metal, plastic and wood. They can be used for a variety of purposes, including cutting out a pattern for a part to be made by other means, making prototype parts and manufacturing small batches of products.

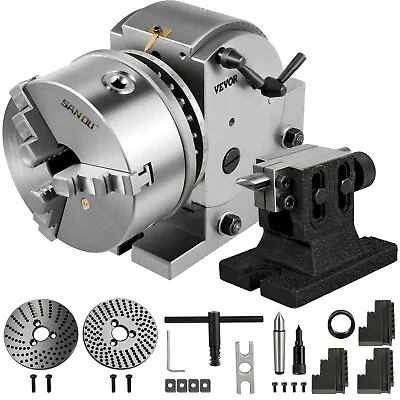

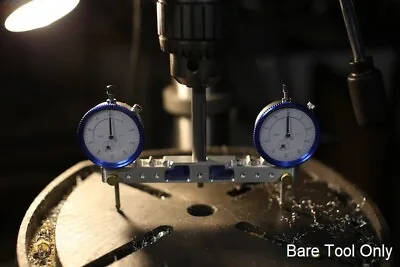

The main components of a milling machine include the table, tool post, spindle and ways. The table is where workpieces are mounted in order to cut or shape them. On most milling machines, the table can be tilted up or down so that you can move it closer or farther away from the tool bit. The tool bit is usually held in place by an adapter called a collet. Collets have different types of jaws at their ends that grip onto different types of tools with various sizes of shanks. When you mount your workpiece on the table, you position it so that it lines up with the bit at its center point (called its centerline). Then you move the table back and forth until it cuts into your material evenly all around its perimeter.

There are many different types of mills available today, each with their own unique benefits and drawbacks. Here's a quick overview of the most common types:

Lathes

Lathes are used for shaping metal objects by cutting away material from them. Lathes can be divided into two main groups: manual lathes and CNC lathes. Manual lathes rely on hand tools for cutting and shaping metal objects, while CNC (computer numerical control) lathes utilize computerized machines that allow for more precise measurements and cuts.

Turning centers

Turning centers are similar to CNC lathes but are designed for use in manufacturing plants instead of shops or garages. They allow for faster production rates than manual lathes but at greater costs due to their sophisticated programming systems, which require extensive training programs in order to operate properly.

Basic Types of Milling Machines

A vertical milling machine has the spindle and table at an angle with respect to each other, while a horizontal milling machine has them parallel. The type of job determines which type is best for use.

Vertical Mills

A vertical milling machine is ideal when you have large pieces that need cutting down or re-shaping because they provide more stability than horizontal mills do when they’re cutting vertically. Vertical mills also work well when making parts from metal stock because they can easily handle larger pieces than horizontal mills can accommodate.

Horizontal Mills

Horizontal mills are probably the most popular type of milling machines on the market today. It's better for making smaller parts and working on other projects that don’t require vertical movement such as drilling holes through metal sheets.

Your request is processing... Please Wait

Your request is processing... Please Wait